Cite commentary

IEA (2022), Reducing the impact of extractive industries on groundwater resources, IEA, Paris https://www.iea.org/commentaries/reducing-the-impact-of-extractive-industries-on-groundwater-resources

What links minerals, fossil fuels and groundwater resources?

Water and energy underpin our economies and societies. Water is needed at every stage of energy production, while energy is essential for the provision and treatment of water. This interdependency has significant implications for both energy and water security. With both water and energy needs set to increase, it has become ever more important to understand the linkages between the two, to anticipate future stress points and to implement policies, technologies and practices to manage these inter-connected challenges.

World Water Day 2022 highlights the need to carefully and sustainably use groundwater, the water that is found beneath the Earth’s surface. Extractive industries are a key part of this equation. They produce oil, natural gas and a range of critical minerals, all of which are fundamental to energy security. They also impact both the quality and quantity of our freshwater resources.

Drilling and excavation often directly encounters aquifers, posing contamination risks. Dewatering (when groundwater inflows are pumped out to maintain access to mines) can cause a decrease in the surrounding water table, or contaminate nearby aquifers.

Indirect impacts can also ensue. Acid mine drainage, resulting from water flows coming into contact with sulfide-rich materials, can occur during mining and persist long after mining has ceased. Tailings ponds, commonly used to store mining waste, pose a contamination risk to downstream water bodies, including nearby groundwater. Water that comes out of oil and gas wells can have high salinity and contain chemical products and residual hydrocarbons, potentially affecting soil and groundwater quality.

Water is often produced as a byproduct during the extraction of oil and natural gas. The discharge of this effluent, which generally has high salinity and contains chemical products and residual hydrocarbons, can potentially affect soil and groundwater quality.

Activities, impacts and risks of extractive industries related to groundwater

|

Industry |

Activities |

Impacts |

Risks |

|---|---|---|---|

|

Mining |

|

|

|

|

Oil and gas |

|

|

|

Fossil fuels and critical minerals require large volumes of water throughout their supply chains

Supplying oil, natural gas, coal and the critical minerals used in the energy sector requires billions of cubic metres of water each year. Water is used along the entire supply chain, from exploration to processing and transport, as well as in many standard operations, such as cleaning, cooling, dust control and pumping.

Unconventional oil and gas operations use particularly large amounts of water. Hydraulic fracturing involves injecting high pressure water mixed with chemicals to extract tight oil or shale gas resources. Studies have shown that unconventional wells often require over 15 million liters of water per year and that this water footprint has been intensifying over the years. Groundwater resources are particularly vulnerable to these activities. Likewise, oil sands surface mining requires 3-4 barrels of water per barrel of heavy oil, while processes to produce other bitumen resources use an average of 0.4 barrels of freshwater per barrel of production, most of which comes from groundwater resources.

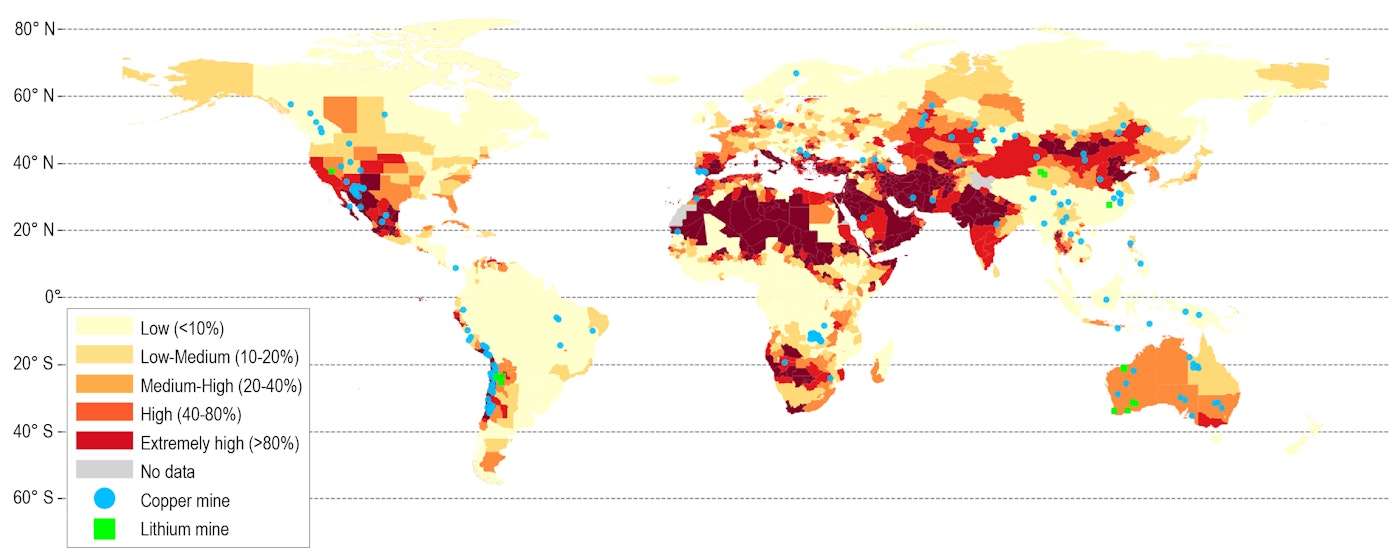

Among critical minerals, copper and lithium are particularly vulnerable to water stress given the location of mines and their high water requirements. Over 50% of today’s lithium and copper production is concentrated in areas with high water stress levels, such as Northern Chile or Australia, and this proportion is set to increase. As climate change causes more frequent droughts and alters water flows, the availability of high-quality water resources will become a crucial factor affecting stable minerals supplies.

Location of copper and lithium mines and water stress levels, 2020

Open

There is growing concern that lithium production based on evaporation pools, where lithium-rich water is pumped to the surface and left to evaporate, is impacting water balances in already water stressed regions. This process requires about 2 million litres of water per tonne of lithium produced. Recent studies identified a negative correlation between the continuous expansion of lithium extraction activities and the soil moisture index, a proxy for drought conditions.

Clean energy development can reduce water stress

Energy choices can support sustainable water management. Clean energy technologies such as wind and solar PV generally come with a lower water footprint than fossil fuels (e.g. coal-powered generation) as they require less water for cooling processes. A shift from coal or oil to natural gas can also lead to lower water requirements.

Freshwater use for the production of selected minerals and fuels

OpenExtractive industries can directly reduce their water needs or switch to alternative sources. Water use can be cut by controlling losses (e.g. minimising wet areas or filtrating tailings) or using dry processing technologies. Mining operations can also use water that has lower quality, such as water from mine dewatering and surface runoff, as well as recycled process water, produced water, treated wastewater or desalinated seawater. Meanwhile, new developments, such as direct lithium extraction technologies, promise to reduce the need for water in the initial steps of production.

To reduce the discharge of pollutants, companies can minimize water contamination (e.g. by managing runoff or covering waste rock and ore piles) and prevent it from reaching waterbodies (e.g. through drainage systems or designing the project to avoid contact with groundwater).

Furthermore, multiple technologies can remove contaminants present in effluents. These include both simple measures (e.g. pH correction and the use of coagulants to precipitate metals) and advanced technologies, such as membrane filtration or photochemical oxidation.

Policies can ensure the water-energy nexus is sustainably managed

Groundwater faces competing demands from agriculture, households and industry, including fossil fuel extraction and mining. Over-use can deplete or pollute aquifers, leading to increased water stress and impacts on ecosystems. Regulatory frameworks that specifically address groundwater can ensure sustainable management.

For example, in 2005 Chile amended existing legislation to take groundwater management into account, defining and allocating groundwater property rights, regulating its use, establishing user associations and enabling the reallocation of rights through market mechanisms. These measures aim to safeguard water flows to sensitive ecosystems and ensure that water levels and quality matches intended uses, with restrictions that kick in when reservoir levels decline or risk of contamination rises.

The industry has been looking to keep pace with these developments. Anglo American, for example, took measures to enable its Los Brondes mine to recycle over 78% of the water it uses by upgrading a water transport system and using an automated circuit for recirculation.

Policy instruments can strive for a sustainable management of groundwater resources through an integrated approach that manages water systems at a basin level and involves multiple stakeholders in co-ordination efforts. Regulators should implement policies sooner rather than later, to avoid the risk of reservoirs being overexploited before policy measures come into effect.

Reducing the impact of extractive industries on groundwater resources